Recommended cutting conditions on the cutting tool catalogue is not often suitable for your machininng process.

I also know that.

This function is not made to estimate the recommended cutting condition.

The object of this function is to find the parameter which is important on the recommended cutting condition.

My hypothesis is that the shape of the throw away insert, which are obtained from the catalogue, shows it's own performance.

Thus, this function is made to research the relationship between recommended cutting conditions and the indexable insert shape.

494 recommended cutting conditions (cutting speed and feed per tooth) are collected with shape data of indexable inserts according to the cutting tool catalogue.

The shape data are shown as follows;

- Approach angle

- Thickness

- Internal circle

- Maximum axial depth of cut

- Number of corner

- One-side or double side

- Tangential or round

True rake angle, inclination angle, edge preparetion and the insert material are important, too.

However, these values are not written on the cutting tool catalogue and it is difficult to measure them.

Thus, I cut off these parameters.

Workpiece material data is summarized as follows;

- (P)Soft steel: 0-180HB

- (P)Steel: 180-350HB

- (P)Alloy steel: 0-350HB

- (P)Die steel: 200-220HB

- (M)Stainless steel

- (K)Cast iron: 0-350MPa

- (K)Ductile cast iron: 0-800MPa

- (N)Aluminum alloy

- (S)Heat resistant alloy

- (H)Hardened steel:HRC40-60

Many variables are made from these parameters.

For example, moment of inertia of area, difficult-to-cut ratio and maximum stress.

And, square root, square, reciprocal of these parameters.

Multiple regression analysis is used for these values.

At this time, these results are obtained.

- Cutting speed on each workpiece material are determined by the workpiece material. The indexable insert shape has no concern.

- Main trend of feed per tooth is determined by the approach angle. Local trend is determined by the workpiece material.

Thus, cutting speed and feed per tooth is calculated by these parameter.

- Cutting speed: workpiece material

- Feed per tooth: approach angle, workpiece material

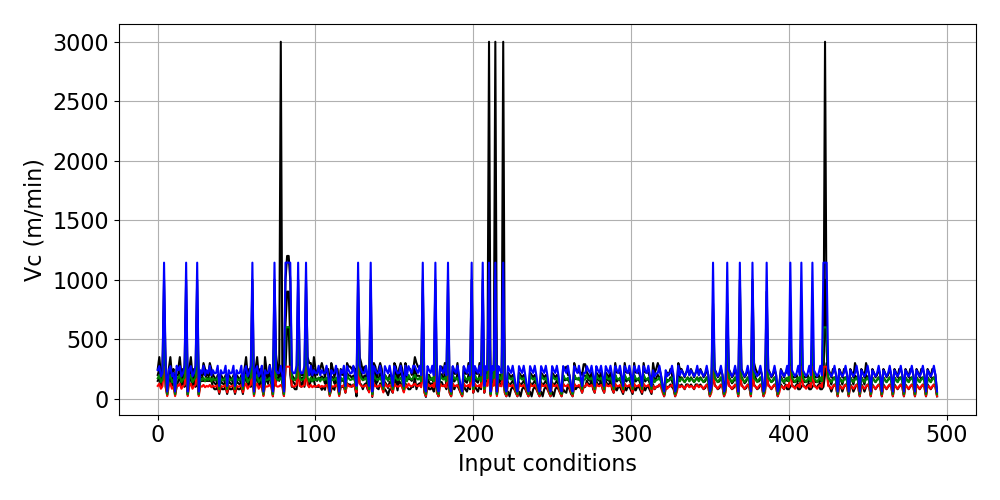

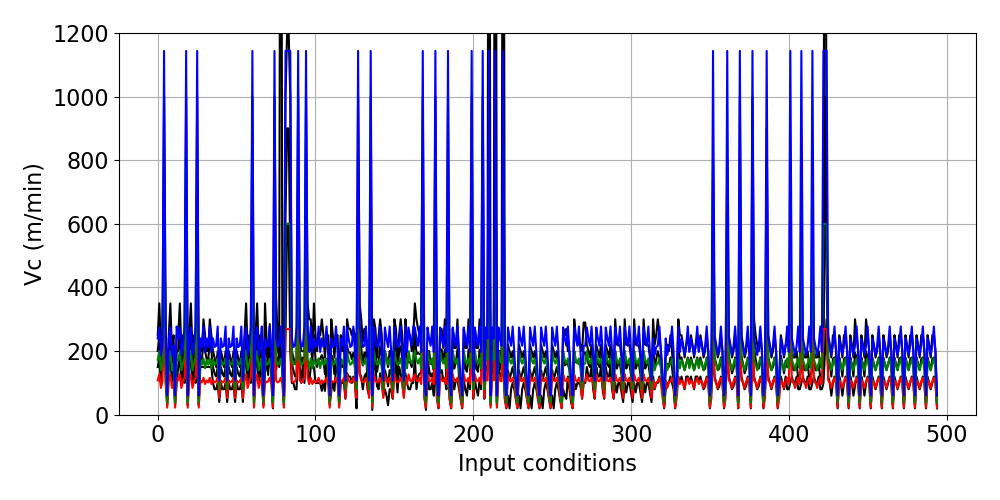

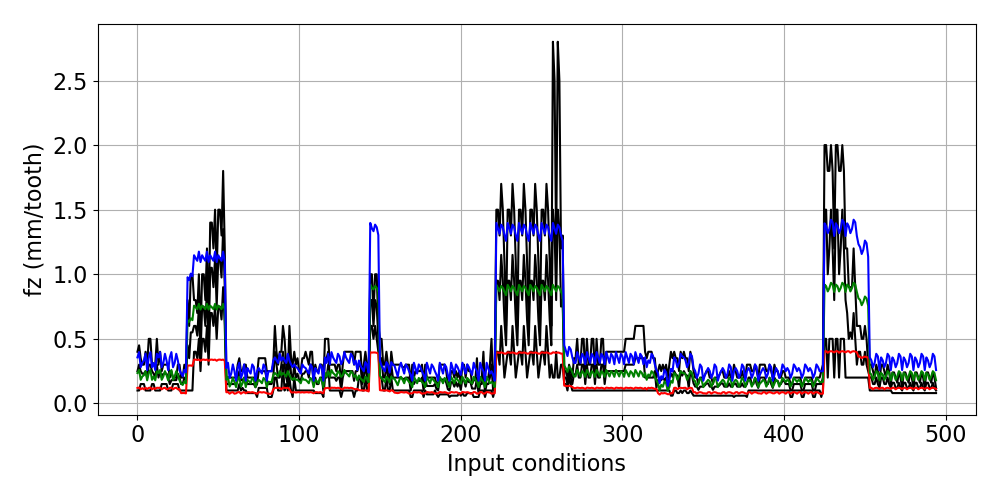

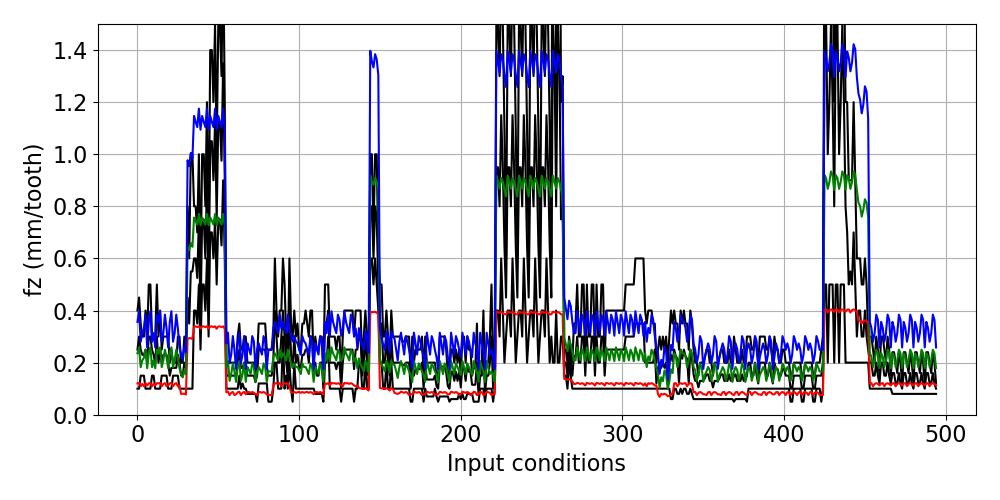

You can check these estimation erorrs from following figures.

On each figures,

Blue lines shows maximum values of estimated results.

Green lines shows middle values of estimated results.

Red lines shows manimum values of estimated results.

Black lines shows recommended values on the cutting tool catalogue.

Fig. Recommended and estimated cutting speed

Fig. Recommended and estimated cutting speed (Magnified)

Fig. Recommended and estimated feed per tooth

Fig. Recommended and estimated feed per tooth (Magnified)

I am going to keep researching this relationship.

The best way to check recommended cutting conditions for your cutting tools is to check the cutting tool catalogue.

Thus, if you want to know the recommended cutting conditions, you have to open and read the cutting tool catalogue without using this function.

You can refer to estimation results by this function, but you must not believe these.

If you use these estimation results, you have to start with lower cutting speed and lower feed per tooth for your safety.