When the front edge and the back edge machines the workpiece, the workpiece surface has the crosshatch.

When the back edge does not machine the workpiece, the crosshatch does not occur.

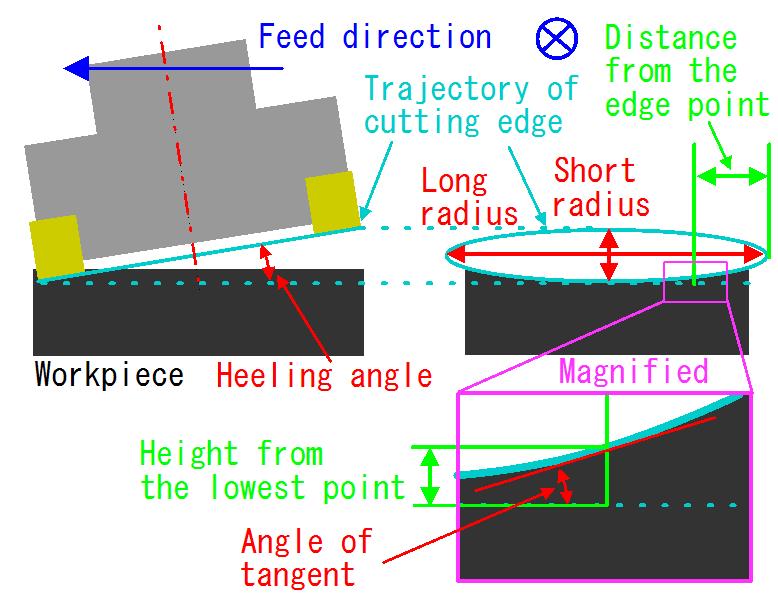

To cause the situation, the main spindle is tilted in the feed direction.

That method is called as "heeling".

When heeling is used, the workpiece surface is not the plane.

The effect of heeling to the workpiece surface is calculated on this function.

When the trajectory of the cutting edge at heeling is watched from the feed direction, the shape is the ellipse.

The long radius and the short radius of the ellipse are shown as follows;

\(\displaystyle R_{long} = \cfrac{D_{t}}{2} \)

\(\displaystyle R_{short} = \cfrac{D_{t} \sin(\theta_{heeling})}{2} \)

\( R_{long} \): Long radius

\( R_{short} \): Short radius

\( D_{t} \): Tool diameter

\( \theta_{heeling} \): Heeling angle

Ellipse equation and tangent equation of ellipse are shown as follows;

\(\displaystyle \cfrac{x^2}{R_{long}^2} + \cfrac{y^2}{R_{short}^2} = 1 \): Ellipse equation

\(\displaystyle \cfrac{x_{0}}{R_{long}^2}x + \cfrac{y_{0}}{R_{short}^2}y = 1 \): Tangent equation of ellipse

\( x_{0} \): X coordinate of a point on the ellipse

\( y_{0} \): Y coordinate of a point on the ellipse

You can calculate the workpiece shape from these equations.